architecture of continuity

1:1 Scale Prototype printed on WASP Crane

2019

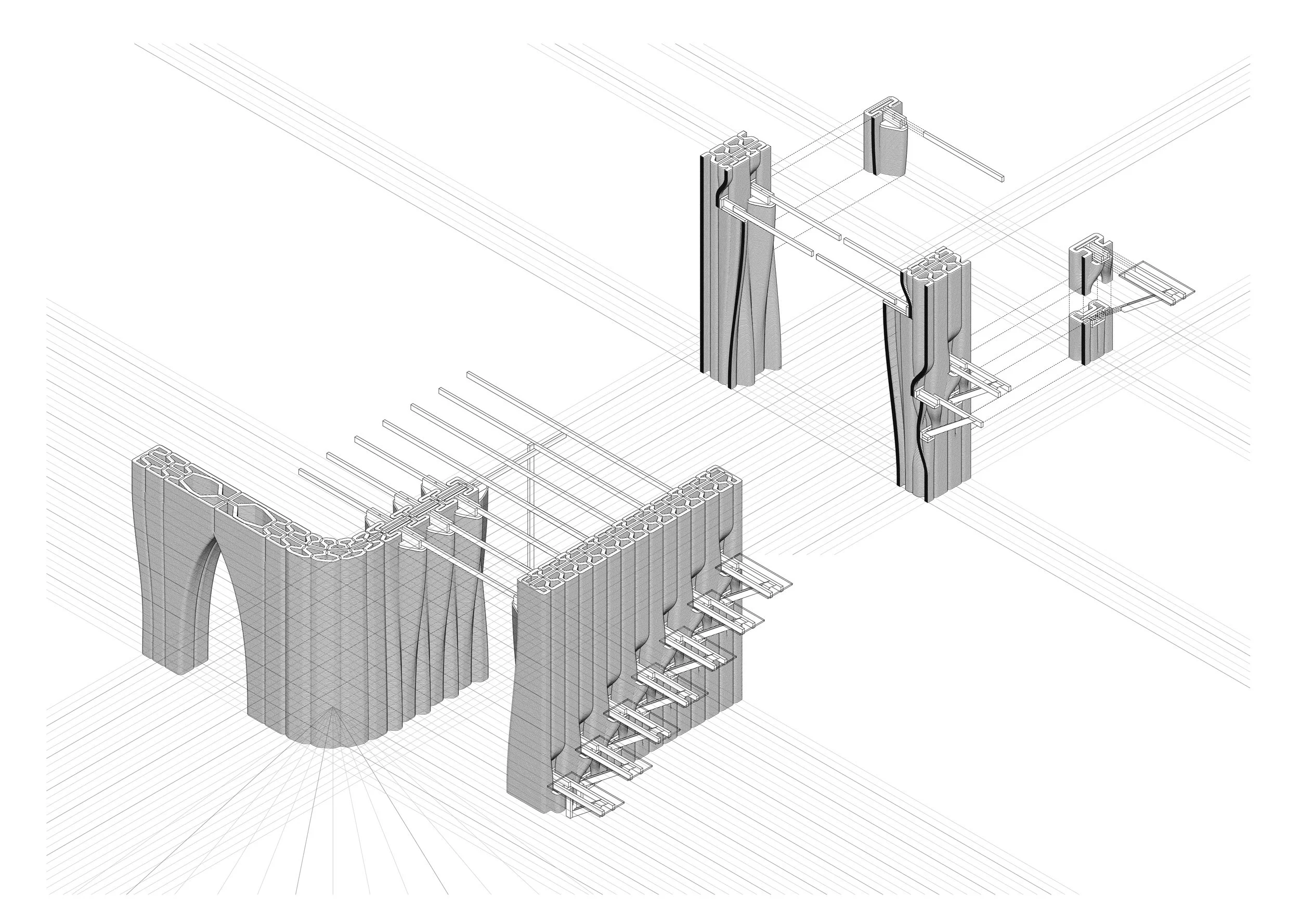

This project was developed during the Open Thesis Fabrication program with a team of researchers as part of my Master’s degree at IAAC. The aim was to create a sustainable and structurally stable construction system using km-0, adobe-based materials with robotic additive manufacturing. The research focused on continuous printing and cantilever geometries to enhance both the structural performance and spatial qualities of the design. Over the six-month research period, we printed several prototypes using a combination of custom-mixed materials and large-scale 3D printing machines.

We selected typical architectural elements as prototypes: an arch opening to connect horizontal spaces, a staircase to connect vertical spaces, and a cantilevered wall to support beams. Wooden joineries were embedded in the clay wall during printing, and the steps and beams were attached to the joineries afterwards.

1:3 Scale Prototype printed on KUKA KR150